Floarea-soarelui

Sunprofi header

The Sunprofi Series is a modern solution for the sunflower harvest. The header has an exceptionally rigid and reliable structure. It affords a problem-free crop harvest under diverse conditions. This is the best harvesting machine for varieties of sunflower with variable stalk height and thickness. Thanks to its long and broad lifters, it is extremely suitable for both normal sized and very tall (confection type) sunflower crops.

Caracteristici tehnice:

- Reinforced lifters of 1,800 mm length with adjustable clearance between them;

- Hydraulic cylinders with which the combine harvester operator can regulate the reel elevation directly from the booth;

- For Claas combine harvesters, both the reel revolutions and the drawing-in rollers below the lifters can be regulated from the booth;

- A refined harvesting system, in which there is a special interaction between the cutting system, the drawing-in rollers below the lifters, the shield and the impeller;

- The intake auger has no interim support and ensures a smooth and gentle harvest, free of jamming and overloading.

- The best possible materials have been used – heavy duty construction steel for the frame, lifters and shield; tempered burnished shafts and tailor-made bearings with dust and moisture protective film. The lifters are reinforced and will not distort under normal operation.

- Components made by world-leading companies have been used, such as Schumacher knife and fingers system, Optibelt belts, Parker hydraulic components.

A long-term use of the harvesting header is well secured.

Date tehnice:

The header has an exceptionally rigid and reliable structure. It affords a problem-free crop harvest under diverse conditions. This is the best harvesting machine for varieties of sunflower with variable stalk height and thickness. Thanks to its long and broad lifters, it is extremely suitable for both normal sized and very tall (confection type) sunflower crops.

Technical features:

- Reinforced lifters of 1,800 mm length with adjustable clearance between them;

- Hydraulic cylinders with which the combine harvester operator can regulate the reel elevation directly from the booth;

- For Claas combine harvesters, both the reel revolutions and the drawing-in rollers below the lifters can be regulated from the booth;

- A refined harvesting system, in which there is a special interaction between the cutting system, the drawing-in rollers below the lifters, the shield and the impeller;

- The intake auger has no interim support and ensures a smooth and gentle harvest, free of jamming and overloading.

- The best possible materials have been used – heavy duty construction steel for the frame, lifters and shield; tempered burnished shafts and tailor-made bearings with dust and moisture protective film. The lifters are reinforced and will not distort under normal operation.

- Components made by world-leading companies have been used, such as Schumacher knife and fingers system, Optibelt belts, Parker hydraulic components.

A long-term use of the harvesting header is well secured.

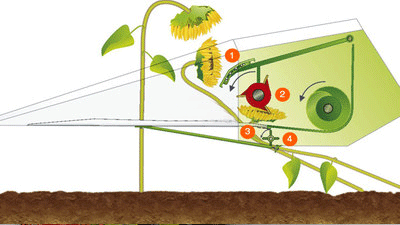

Operating principle

1 Adjustable deflecting shield2 Reel3 Cutting device4 Drawing-in roller

Initially, the sunflower stalk is caught by the lifters. Then, the adjustable shield deflects the flower heads of the sunflower forward. Concurrently, the drawing-in rollers located below the cutting device press the stalks down. In this synchronised action of the shield and the rollers, a premature cutting of the stalks is prevented. The cutting only occurs once the flower heads get caught in by the reel. Thanks to this, only the flower head and possibly a very short bit of the stalk are cut off. Only those are then fed to the intake auger and then to the inclined chamber of the combine harvester. The leaves and stalks remain in the field and do not find their way into the combine harvester.

This unique working principle has the following advantages:

- Increased productivity;

- Lower fuel consumption;

- Lower loading, wear and tear of the combine harvester;

- Clean crop harvest;

- Ability to harvest sunflower of varying height.

Important summary:

The flower head is cut only once the reel catches the head, thanks to which only the sunflower heads fall into the auger and then into the chamber of the combine harvester.

Why a shield and not a pipe?

To economise, some producers use a simple pipe to deflect the sunflower stalks. It is the first thing that meets the sunflower stalks and pushes them forward. This is an easier and cheaper way indeed for the producer. It is a simple solution, but it has its compromises.

What are the disadvantages?

1.The contact area between the pipe and the plant is small. When the stalks are pushed forward, a shaking takes place, because the stalk is in contact with the pipe in one point, and not a surface as is the case with the shield;

2.The sunflower head is not protected from contact with the reel fingers;

3.It does not prevent leaves falling into the auger.

Manufacturers who want the best for the farmers do not do this. They make headers without saving costs because:

1.The shield guarantees a prevention of contact between the flower heads and the reel fingers before the cut and does not allow a loss of seeds;

2.It secures a stable hold of the stalks up to the moment of cutting;

3.It facilitates the plant’s sliding forward without being shaken;

4.The whole leave and stalk mass remaining under the cutting line is guaranteed to stay in the field and not find its way into the combine harvester.

In conclusion, the deflecting shield solution over the deflecting pipe solution makes for better harvest with fewer losses.